Why Quality Assurance is Non-Negotiable

Production Downtime

Production Downtime can cost $22,000 per minute in automotive and electronics.

Counterfeit Components

Counterfeit Components lead to recalls, safety risks, and compliance failures.

Redesign Costs

Redesign Costs from obsolete components can reach $1.5M per occurrence.

Quality Starts at the Source

Virtual Inspections

Evaluation of supplier testing facilities.

Certification Verification

Compliance with ISO, AS6081, and other standards.

Ongoing Monitoring

Regular audits to maintain high-quality performance.

How we Ensure Quality

Supplier Vetting:

Rigorous onboarding with virtual facility inspections and certification verification.

Third-Party Testing:

Partnership with accredited labs for advanced analysis.

Component Inspection:

Visual checks, electrical testing, and X-ray analysis.

Why Quality Assurance is Non-Negotiable

We are ISO 9001:2015 certified and fully compliant with IDEA-STD-1010-B, ensuring best-in-class quality management and counterfeit detection.

Collaborations with accredited labs for comprehensive component testing.

Every supplier undergoes a thorough evaluation to meet our quality standards.

Certifications & Accreditations

View All DocumentsISO 9001:2015

Certified Quality Management System ensuring consistent products and services.

AS9120 Rev B

Aerospace standard for stockist distributors, ensuring chain of custody.

ANSI/ESD S20.20

Electrostatic Discharge Control program for protection of electrical parts.

ERAI Member

Member of the Electronic Resellers Association International for risk mitigation.

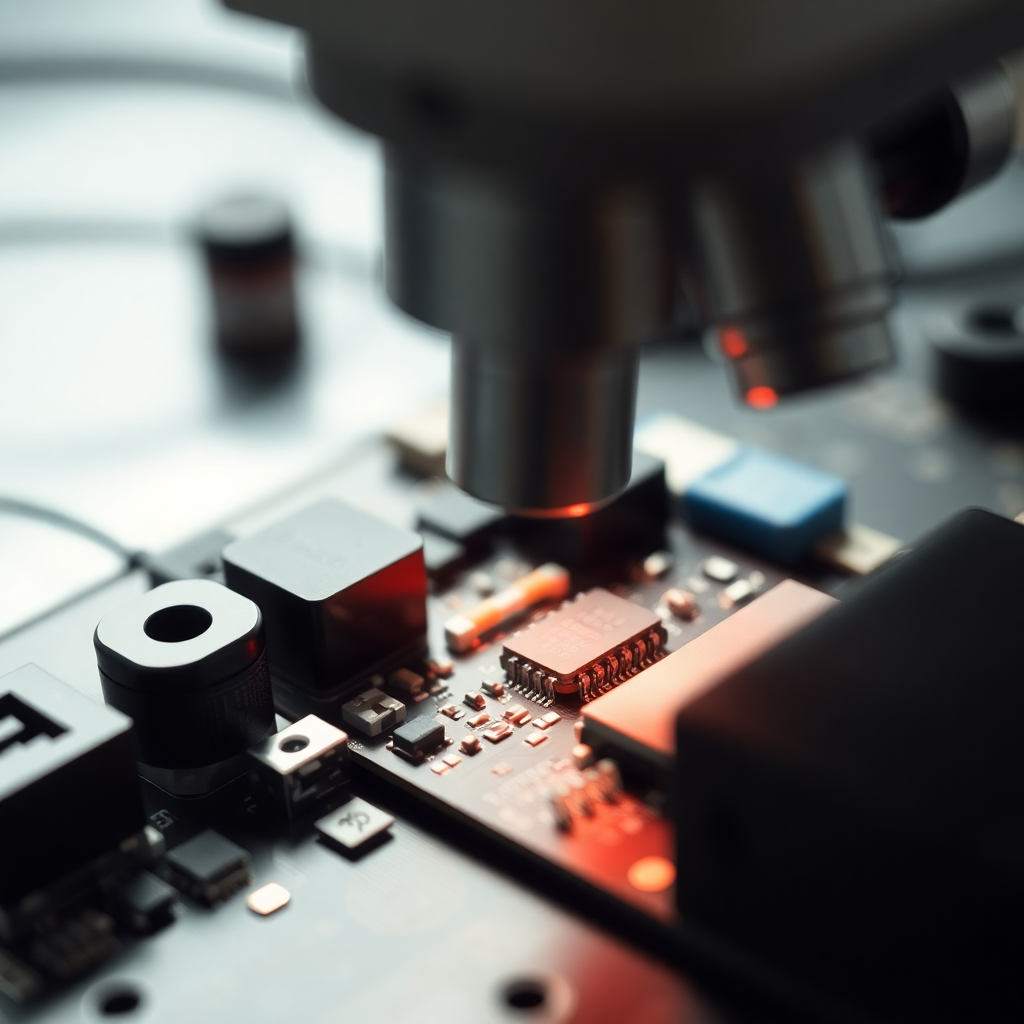

In-House Inspection Workflow

Receiving & Documentation

Visual inspection of packaging, label verification, barcode scanning, and ESD compliance check upon arrival.

Detailed Visual Inspection (DVI)

Microscopic analysis (30x-100x) checking for resurfacing, remarking, lead condition, and body integrity.

Advanced Testing (Tier 2)

X-Ray fluorescence (XRF) for material analysis, Decapsulation for die verification, and X-Ray imaging.

Final QA Release

Generation of comprehensive test report, final count verification, vacuum sealing, and shipment approval.

Lab Equipment Inventory

- Keyence VHX-7000Microscope

- Thermo Scientific XRFAnalyzer

- Glenbrook JewelBox 70TX-Ray

- Nisene JetEtch ProDecap

- HMP4040 Power SupplyElectric

Counterfeit Mitigation

We adhere strictly to AS6081 standards for avoidance, detection, mitigation, and disposition of counterfeit electronic parts.

Inspection Gallery

Lead Condition Analysis

Die Integrity Check

Die Verification

XRF Composition Test

Experience Quality Without Compromise

Don't let shortages disrupt your production.

Trusted by companies from 16 countries for our stringent quality processes

Get a quote now